Why the Right Compressor is Non-Negotiable

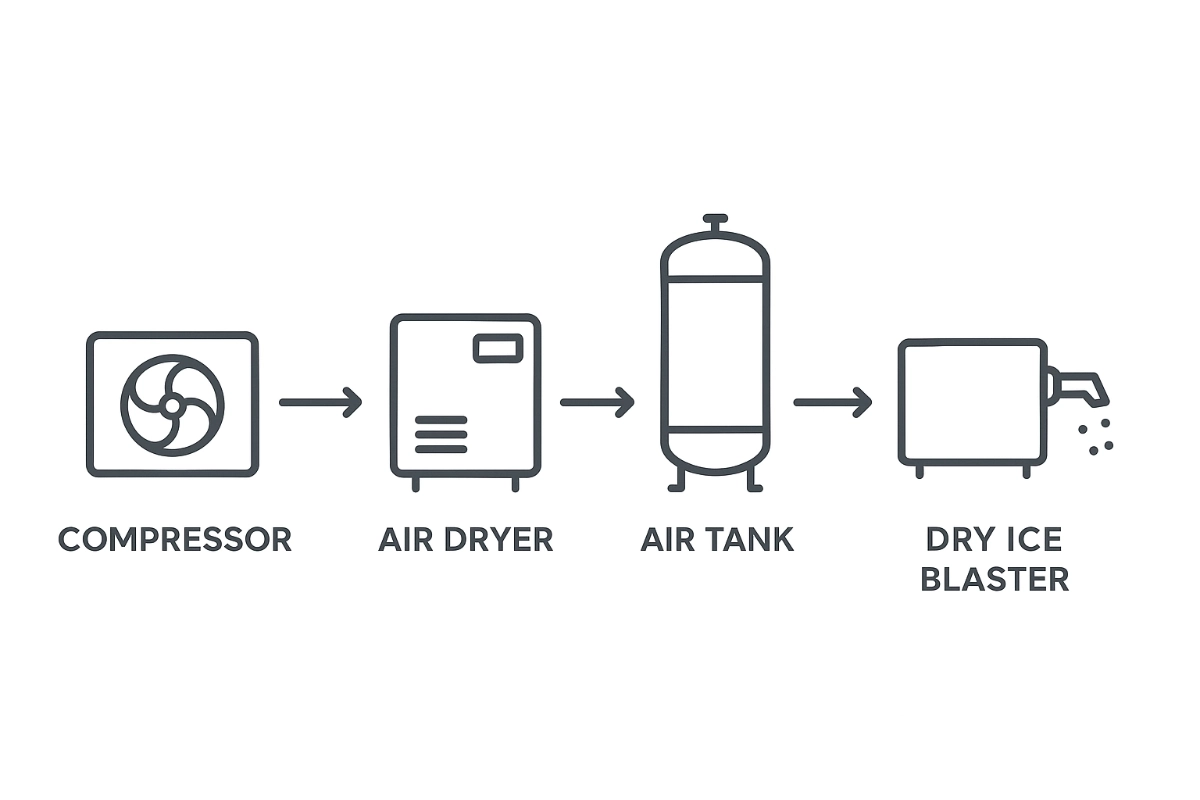

In dry ice blasting, compressed air is the engine. It's responsible for propelling the CO₂ pellets at velocities high enough to strip contaminants from surfaces. An underpowered or mismatched compressor doesn't just slow you down—it compromises cleaning quality and can even damage your equipment.

Understanding air pressure (PSI), air volume (CFM), and air quality is the first step to achieving flawless, efficient, and safe operation.